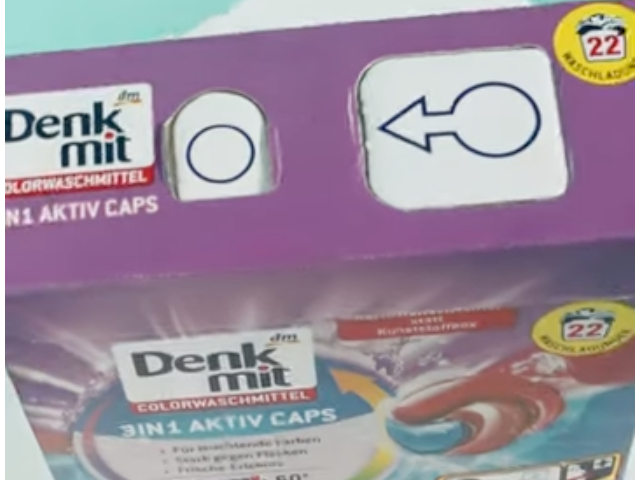

Brohl Wellpappe liefert uns sehr hochwertige und kreative Lösungen für die Umverpackung unserer Getränkedosen und –flaschen und zeichnet sich dabei besonders durch eine exzellente Liefertreue aus.

Eine Idee näher am Kunden

Wir sind ein mittelständisches Familienunternehmen mit langer Tradition und stellen hochwertige Verpackungen und Displays aus Well- und Vollpappe her. Besonders wichtig sind uns Kundennähe, Zuverlässigkeit und Kreativität, denn wir verstehen uns als Partner an der Seite unserer Kunden. Wir haben uns zum Ziel gesetzt, für jede individuelle Anforderung immer die beste Lösung zu finden. Mit maßgeschneiderten Verpackungslösungen, unseren vielfältigen Dienstleistungen und unserer Druckkompetenz leisten wir so einen wertvollen Beitrag zum Erfolg unserer Kunden.

Unsere Technologie

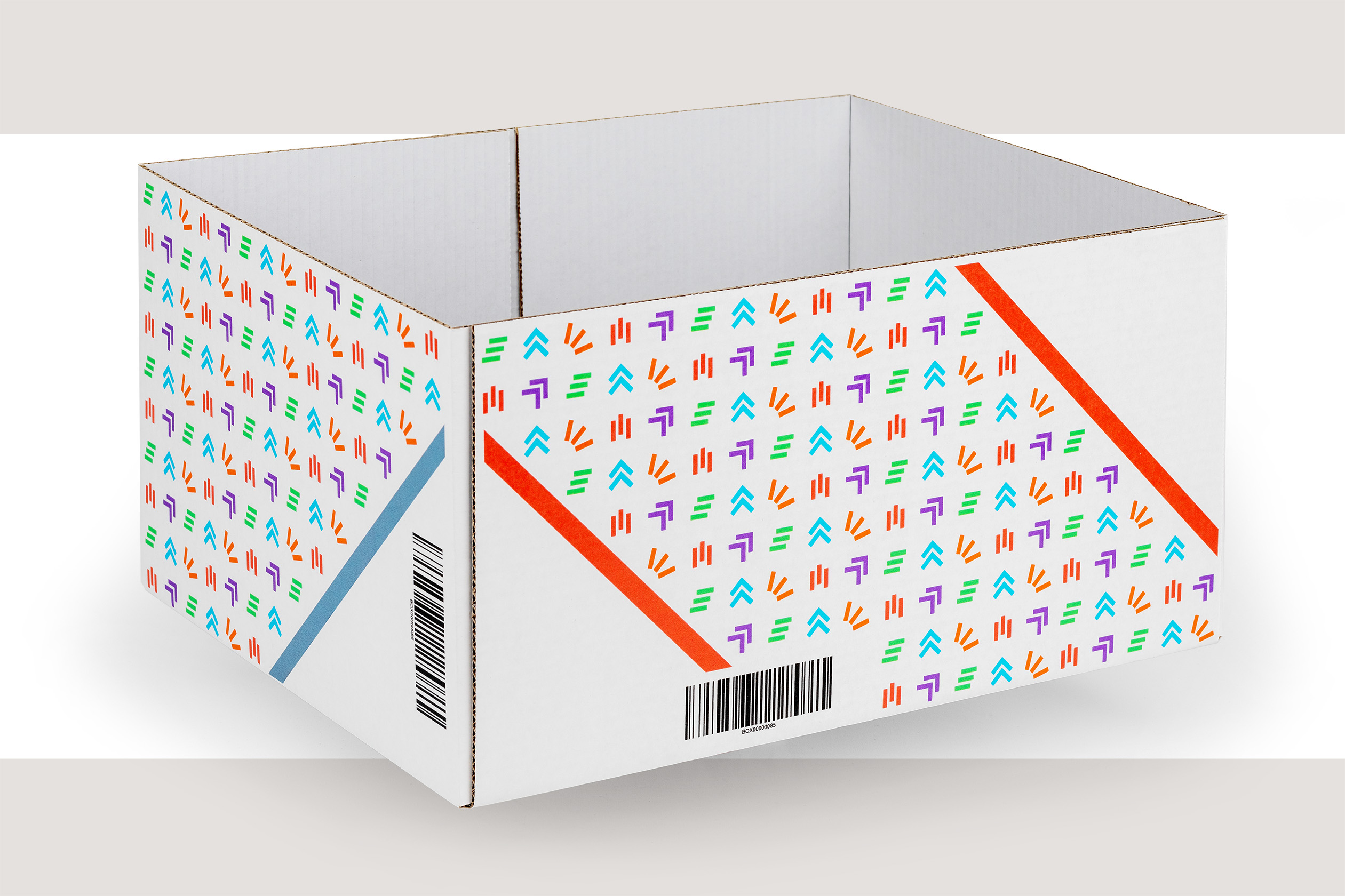

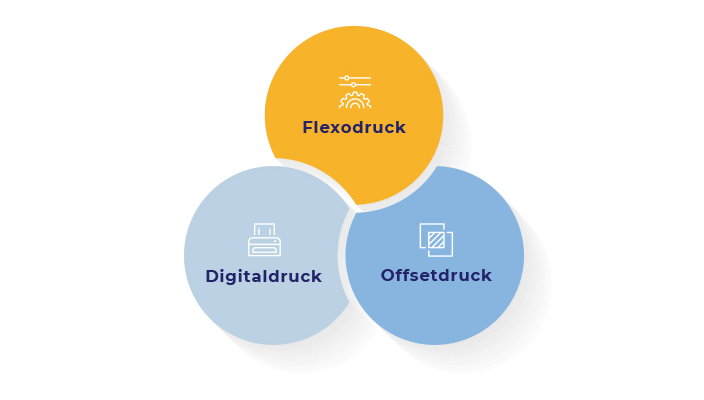

Bei der Präsentation von Produkt, Marke und Hersteller kommt der Verpackung eine zentrale Rolle zu. Ausschlaggebend sind hierbei Gestaltung und Druckqualität. Wir entwickeln Lösungen, die so individuell sind, wie die Produkte unserer Kunden. Dazu bieten wir immer das passende Druckverfahren: Ob hochwertiger Flexovordruck, Flexodirektdruck, Offsetdruck oder Digitaldruck - wir verfügen über die Technik und das notwendige Know-How.

Relaunch unseres Onlineshops

Unser neuer Onlineshop für Weinverpackungen shop.wellpappe.de ist jetzt online! In den letzten Wochen haben die Kolleginnen und Kollegen am Relaunch gearbeitet. Der neue Shop speziell für Weinverpackungen bietet verbesserte Funktionen und ein modernes und ansprechendes Design.

Was gibt es Neues?

1. Verbesserte Suchfunktion: Dank unserer optimierten Suchfunktion finden unsere Kunden jetzt noch schneller und einfacher genau das, wonach Sie suchen: Ob nach Größe, Flaschenanzahl oder Farbe der Außendecke- mit nur wenigen Klicks werden die passenden Produkte angezeigt.

2. Frisches Design: Unser neuer Shop präsentiert sich in einem modernen und ansprechenden Design - für ein verbessertes Einkaufserlebnis.

3. Verbesserte Übersichtlichkeit: Wir haben die Struktur unseres Shops überarbeitet, um eine noch bessere Übersicht über unser Produktsortiment zu bieten.